SEARCH BY KEYWORDS, SUBJECT, PEOPLE AND HIT ENTER

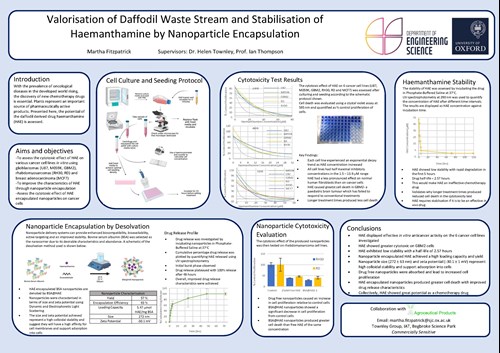

This project was in collaboration with Agroceutical Products, a Welsh bioresearch company who cultivate daffodils for the extraction and sale of the alkaloid galanthamine.

Recently, Agroceutical Products has discovered that for every 1 unit of galanthamine in their daffodil harvest there are 2 units of the alkaloid haemanthamine. Haemanthamine has attracted attention due to its strong anticancer activity but is still not commercially produced due to lack of research.

My project involved assessing the potential of daffodil derived haemanthamine, provided by Agroceutical products, as a chemotherapy agent against various cancer cell lines. After proving its efficacy in killing cancer cells, I investigated the drugs properties.

In finding haemanthamine had a low stability with a short half-life I investigated nanoparticle encapsulation as a method of stabilising the drug. This would provide greater stability in the blood stream allowing longer effective treatment times and could provide active targeting towards tumours in the body. The nanoparticles produced were then tested with respect to their properties and their cytotoxic effect on cancer cell lines.

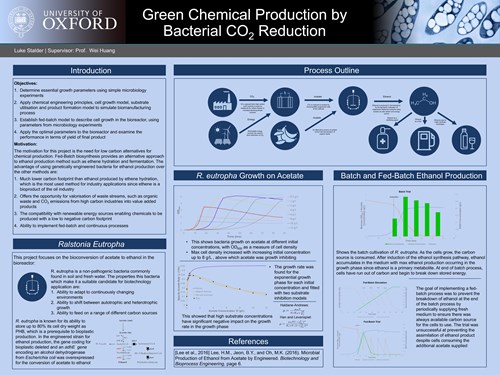

Ethanol is a simple alcohol which has many industrial uses from an alternative fuel to solvents and in the making of alcoholic beverages. Ethanol can be produced through biosynthesis using the bacteria, Raltonia eutropha, and acetate as a sole carbon source.

This, when combined with microbial electrosynthesis and renewable energy sources offers the opportunity as a carbon capture and utilisation option to produce ethanol with a negative carbon footprint.

This project is part of a larger overall goal to implement a complete CO2 to ethanol production system with this study focussing on modelling and optimising the biosynthesis stage in the bioreactor, converting acetate to ethanol.

This project was performed to find and apply a mathematical model to describe and predict the biomanufacturing process of ethanol. Genetically engineered Raltonia eutropha H16 was used to produce ethanol using acetate as the sole carbon and energy source.

The overall objective of the project was to determine essential parameters using simple microbiology experiments and apply them to an ethanol producing bioreactor system. Ethanol would then be extracted, quantified and performance analysed in terms of yield of final product. The operation would then be compared to the theoretical model developed to describe the fed-batch operation.

The laboratory has produced a genetically engineered strain of Raltonia eutropha where the metabolic pathway encoding gene from acetyl-CoA to polyhydroxybutyrate (PH B) was removed and the gene encoding for the conversion of acetyl-CoA to ethanol was overexpressed. The growth characteristic of this strain, the wild type, and the strain with neither the PHB nor ethanol gene coding were analysed under different substrate feeding concentrations and regimes.

Cell growth on acetate was characterised and the inhibitory effects of the substrate modelled. Essential parameters were determined and used to produce a model for the batch and fed-batch cultivation of engineered R. eutropha on acetate as sole carbon source. Optimal parameters predicted by this model and preliminary experiments were implemented in the lab bioreactor setup achieving maximum ethanol accumulation of 0.283 g/L and 0.175 g/L in batch and fed-batch operation respectively.

The purpose of the fed-batch was to improve on the batch process by periodically feeding fresh medium to achieve greater cell densities and product yields. Finally, the ethanol and acetate data collected from the fed-batch trial was then used to analyse the accuracy of a simulation produced for the process.

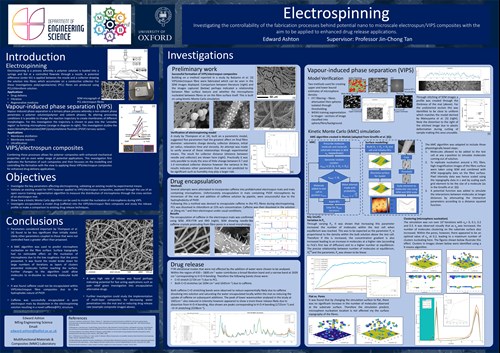

Electrospinning Since the early 1990s, electrospinning has become an increasing point of focus [1] owing to the flexibility with which scaffolds can be created. This enables a wide range of applications, including drug delivery and filtration [2], where inherent porosity of the scaffolds is exploited, and regenerative medicine, where the morphology can be altered to increase cell adhesion and proliferation [3]. Within the field of drug delivery, research is currently being carried out into ways in which personalised drugs can be created, allowing for custom doses and delivery rates.

Electrospun composites show huge potential for this, with many methods of encapsulation and release being investigated from simple mechanisms such as dissolution of a drug into fibres to more complex methods such as coaxial spinning, producing fibres with a drug doped core. In addition, electrospun composites can also be used for altering the drug release and mechanical properties of drug doped materials by combining multiple manufacture processes. These include additive manufacturing and, as discussed here, vapour-induced phase separation (VIPS).

The objective was to study the controllability of the fabrication processes behind potential nano to microscale electrospun/VIPS composites (PCL fibres/PVDF microspheres) with the aim to be applied to enhanced drug release applications. The following investigations were made:

• The effect of the key parameters behind the electrospinning process on fibre diameter were investigated and compared to the results from an existing model from Thompson et al. [4]

• Validation and modelling of two aspects of VIPS (explained below): the ternary phase separation process itself and the nucleation of microspheres.

o Validation of an existing model for VIPS using a 1999 study by Matsuyama et al. [5] for thin, porous membranes and how this applies to microsphere formation in an electrospun mat as experimentally performed by Balzamo et al. [6]. This is explored through the use of an open source training segmentation algorithm to measure microsphere distribution through the thickness of the composite.

o Where average polymer density has been used to find the distribution across a membrane, at the microscale the picture is quite different. A kinetic Monte Carlo algorithm, adapted from Grosfils et al. [7], was used to model microsphere nucleation on the fibre surface at a molecular level. This adapted model implements a realistic substrate surface through the combination of experimental data determined from atomic force microscopy (AFM) and scanning electron microscopy (SEM).

• Methods were explored to encapsulate a model drug (caffeine) into the composites described and modelled above. A variety of methods were attempted including electrospinning of drug doped polymer solutions (forming a novel needle-like morphology studied for the first time within this investigation) and post-electrospinning addition of the drug through a caffeine/water solution. These methods are reviewed based on the penetration of caffeine through the thickness of the mats.

• Drug release rate was found and qualitatively compared to current release methods, showing scope of these novel materials for commercial drug delivery devices.

Bibliography: [1] L. Chen, S. Wang, Q. Yu, P. D. Topham, C. Chen, and L. Wang. A comprehensive review of electrospinning block copolymers. Soft Matter, 15(12):2490–2510, 2019. [2] Zheng-Ming Huang, Y.-Z. Zhang, M. Kotaki, and S. Ramakrishna. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Composites Science and Technology, 63(15):2223 – 2253, 2003. [3] H. Mondesert, F. Bossard, and D. Favier. Anisotropic electrospun honeycomb polycaprolactone scaffolds: Elaboration, morphological and mechanical properties. J Mech Behav Biomed Mater, 113:104124, 2021. [4] C. J. Thompson, G. G. Chase, A. L. Yarin, and D. H. Reneker. Effects of parameters on nanofiber diameter determined from electrospinning model. Polymer, 48(23):6913–6922, 2007. [5] Hideto Matsuyama, Masaaki Teramoto, Ryo Nakatani, and Taisuke Maki. Membrane formation via phase separation induced by penetration of nonsolvent from vapor phase. i. phase diagram and mass transfer process. Journal of Applied Polymer Science, 74(1):159–170, 1999. [6] Gianluca Balzamo, Xiyu Zhang, Wolfram A. Bosbach, and Elisa Mele. In-situ formation of polyvinylidene fluoride microspheres within polycaprolactone electrospun mats. Polymer, 186:122087, 2020. [7] Patrick Grosfils and James F. Lutsko. Impact of surface roughness on crystal nucleation. Crystals, 11(1):4, 2021.