SEARCH BY KEYWORDS, SUBJECT, PEOPLE AND HIT ENTER

Poster supporting statement Irinka Lamiquiz Pratt

In a new technological era, the monitoring of forces and displacements is becoming increasingly essential in a wide range of applications within many high value sectors, e.g. civil and structural engineering, renewable energy and healthcare. Innovative developments in prominent industries such as aerospace and robotics have propelled innovation and growth in the force sensor market in recent years.

However, increasingly complex sensor structure designs and instrumentation procedures, along with a lack of adequate sensor designs which are damage resistant and robust to electromagnetic interference, call for a new solution to force sensing to be developed.

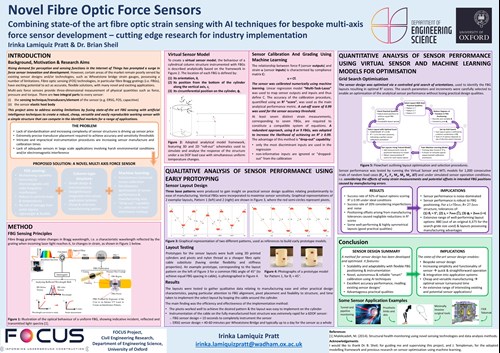

Therefore, the aim of this project was to address existing limitations through the design and development of a novel concept, multi-axis force sensor based on fibre optic sensing and artificial intelligence technology. Specifically, this project explores and optimises the instrumentation of fibre Bragg gratings on a cylindrical sensor body to form a robust, reliable, versatile, economically feasible and straightforward to manufacture sensor.

A range of candidate layout patterns were considered. The layout patterns are defined by the orientation, axial position, and circumferential position of the FBGs in the layout. Emphasis was placed on assessing the accuracy, sensitivity, flexibility and manufacturing feasibility metrics of each pattern.

A physical study was undertaken using early prototyping to gather qualitative information on practical sensor layout qualities, such as time taken to instrument the sensor. Important results include the success of the instrumentation procedure in implementing the desired layout relatively quickly and easily.

Machine learning was subsequently used to optimise the FBG layout design for excellent sensor performance and practicality/ease of sensor manufacturing simultaneously. The sensor’s accuracy and sensitivity performance was assessed analytically: a virtual sensor model was created using Python programming and a Multi-Task-Lasso was used to calibrate the model numerically, using a carefully selected set of force to simulate typical experimental calibration methods.

An R2 function was used to quantify the sensors accuracy for each layout design by comparing the extent of the MTL in reflecting the expected linear load-strain relationship, with an R2 score greater than 0.99 being the acceptable cut-off. Finally, a controlled grid search was performed to cross-reference the sensor layout designs achieving optimal R^2 scores and possessing practical qualities.

The layouts were tested using the trained model under randomly generated load combinations, approximating real sensor operation conditions with noisy measurements and manufacturing imperfections.

The series of analyses successfully yielded a final list of 880 (out of 4,375) suitable orientation combinations surpassing a lower bound limit of R2 ≥ 0.99, thus constituting a substantial range of transducer layout options with both optimal analytical performance and practical advantages, for use in sensor design.

In conclusion, an analytical method to identify optimal transducer layouts was successfully developed and is scalable, flexible and adaptable to different sensor applications as well as being practical enough to suit opportunities in the force sensor market. The data collected is promising and may be used in future investigation as a valuable reference or a solid base to build upon.

Max Bowman; Supervised by Prof. Harvey Burd & Prof. Wes Armour

MACHINE LEARNING TECHNIQUES TO ESTIMATE THE STIFFNESS OF OFFSHORE FOUNDATION

In June 2019, the United Kingdom pledged to become carbon neutral by 2050. With the power sector making up 15% of the UK’s current total CO2 emissions, and energy consumption forecasted to increase, further investment into renewable energy sources will be key to meeting this commitment.

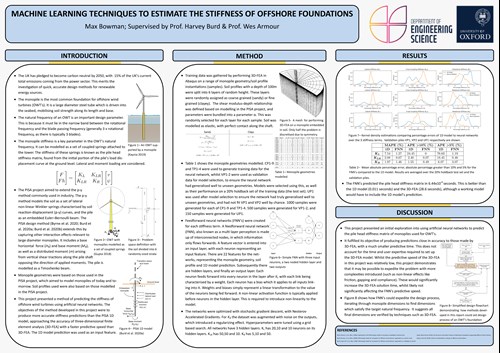

The UK has targeted an offshore wind power capacity of 40GW by 2030. This requirement for an increase in capacity merits the investigation of quick, accurate design methods. The monopile is a foundation commonly used to support offshore wind turbines. The stiffness of the foundation is a key parameter in predicting the natural frequency of offshore wind turbines, which are regularly exposed to cyclic loading from wind, waves and rotor excitations.

This project presented a method of predicting the stiffness of offshore wind turbines using artificial neural networks. Neural networks were trained using results from three-dimensional finite element analysis over a range of monopile geometries and soil profiles. Input features were supplemented with results from a one-dimensional model based on the PISA modelling approach (Byrne et al. 2020; Burd et al. 2020a; Burd et al. 2020b) which provided a 'base estimate' for the networks to further refine. Soil was divided into six strata of random height which were randomly assigned to be fine-grained (clayey) or coarse-grained (sandy). There were a number of simplifications in the finite element analysis. Soil was modelled as linear elastic, and perfect contact was assumed between the pile and the soil.

The objective of the method developed in this project was to approach the accuracy of three-dimensional finite element analysis whilst expediting the process. This could be used in design to iterate through monopile geometries before verifying the final design with a technique such as finite element analysis.

This project served as an initial exploration into using neural networks to predict the pile head stiffness matrix of monopiles, and recommendations for future work were suggested.

The results of this project suggest this method could be applicable for modelling the problem with additional complexities introduced. Neural networks were able to make predictions approaching the accuracy of three-dimensional finite element analysis with a much lower computational cost.

Over the test and validation set of monopile geometries, the networks were able to predict the three terms making up the pile head stiffness matrix with mean absolute percentage errors of 1.27%, 0.67% and 1.46%.

The validation set was made up of geometries not found in the training set to ensure the networks had generalised well to unseen geometries.

References Burd, Harvey J. et al. (Nov. 2020a). Application of the PISA design model to monopiles embedded in layered soils. Burd, Harvey J. et al. (Nov. 2020b). PISA design model for monopiles for offshore wind turbines: application to a marine sand. Byrne, Byron W. et al. (Nov. 2020). PISA design model for monopiles for offshore wind turbines: application to a stiff glacial clay till.