SEARCH BY KEYWORDS, SUBJECT, PEOPLE AND HIT ENTER

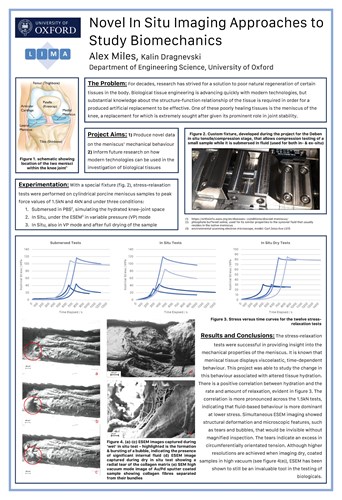

Novel In Situ Imaging Approaches to Study Biomechanics

Alex Miles

Context:

The meniscus is a fibrocartilage and one is located within each of the medial and lateral compartments of each knee. It is similar in composition to the articular cartilage also present in synovial joints. Naturally containing around 70% water, its solid matrix consists mostly of a specifically orientated collagen fibre network (orientation reflecting the mechanical purpose of each region).

The structural matrix is interposed with cells called chondrocytes that help in maintenance of the network. Most of these cells receive nutrition through diffusion from the synovial fluid, which also serves to lubricate the joint, and they do not have access to vasculature like most other tissues of the body. As such, the meniscus’ ability to heal and repair is poor. Its roles include stabilising the knee joint, favourably distributing load and also distributing the synovial fluid, ensuring nourishment of other avascular structures. It was thought to be a benign and removable feature for a long time, but in recent decades a strong correlation between removal of the meniscus and the development of osteoarthritis has been noticed. Removal is performed if a damaged meniscus is causing extra friction in the joint but doing so massively increases peak stresses experienced by the adjacent articular cartilage of the major leg bones.

Hence the recent focus on finding treatments that preserve, renew or even artificially replace the meniscus.

Project Aims and Conclusions:

The ESEM is a great tool for viewing micro- and even nano-scale features of a material, length scales that are extremely beneficial in this context.

However, a major drawback is the need for imaging to be done in a partial or full vacuum. Conventional electron microscopy can only be done on conductive samples in a high vacuum. ESEM is an extension to this that allows fluids in the specimen chamber, at the expense of image quality. The meniscus is known to respond to load viscoelastically and thus displays time-dependent behaviour. Its native loading environment is primarily axial compression – carrying body weight transferred through the femur.

Hence the decision to perform compression testing, specifically stress-relaxation as this allows investigation of both strain- and time-dependent behaviours. Viscoelastic behaviour of the meniscus is based largely on interactions between its porous extracellular matrix and the drag associate with fluid being forced through it.

This is the rationale behind investigating the affect that dehydrating the sample had on its behaviour, as some dehydration is inevitable when imaging under the ESEM in a low-pressure, gaseous chamber.

The project was successful in using in situ mechanical testing to determine a relationship between sample hydration and mechanical behaviour. This both provided novel information about properties of meniscal tissue and helped to inform any future study that aims to use mechanical testing in combination with ESEM imaging, especially in the context of hydrated biological samples.

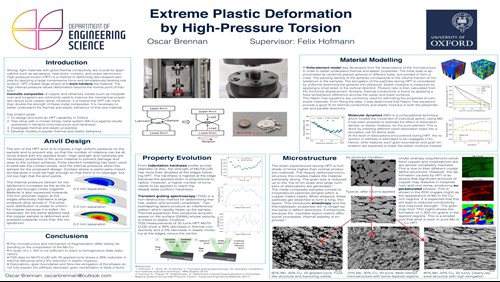

Since ancient times copper and its alloys have been used for their excellent conductivity, resistance to corrosion, workability, and resistance to fatigue. Yet for certain critical applications copper is limited by its poor mechanical strength and high co-efficient of thermal expansion. Metal matrix composites of copper with refractory metals such as tungsten and molybdenum increase the hardness and temperature resistance while also reducing thermal expansion. Their use is widespread in heat sinks, thermoelectric devices, and aerospace where reasonably good conductivity and strength are needed. However, a more refined microstructure with smaller grain sizes would significantly improve strength, allowing for their usage in more demanding applications.

Other techniques such as powder sintering have produced Cu-W nanocomposites with grain sizes of a few 10s of nanometres, but impurities from the milling process are detrimental to the thermal and electrical conductivity. Blacksmiths realised that repeated hammering was necessary to produce harder swords and knives, even if the underlying process for this was unknown. Now it is well understood that increasing the number of material defects improves strength, yet this work hardening of most materials is limited by failure at relatively low strains.

Severe plastic deformation techniques such as high-pressure torsion permit very high strains without fracture of the sample, producing ultra-fine-grained microstructures and a large increase (up to 300%) in hardness. In high-pressure torsion, a disc-shaped sample is subjected to a large axial load while one surface is simultaneously rotated. The anvils for this project were based off existing designs modified after finite element simulations, made from high-strength tool steel.

Numerous experiments with pure elements or alloys have demonstrated rapid increases in hardness and refinement of the microstructure following HPT. While hardness, microstructure, and thermal stability have been extensively studied, there has been almost no research on the effect to the elastic modulus and thermal conductivity.

More recently, there has been some interest on combining HPT with insoluble metal matrix composites. The development of the microstructure is far complicated: depending on the hardness of the phases and their volume fractions, fine layers or stretched, coarser particles may appear. For the Mo-Cu system investigated in this project, the micrographs of each composition are noticeably different. However, the applied strain was not sufficient to reach a homogeneous state.

Nonetheless, the samples produced had a sufficiently refined microstructure for analysis to show significant changes in thermoelastic properties. A future direction would be the investigation of heat treatment. For example, annealing should be used to remove some of the defects which reduce thermal conductivity, though care must be taken to prevent a large loss in strength.

The fine phase structure provides exceptional thermal stability by preventing diffusion through the alternating layers. Owing to the small sample size in HPT processing, the method is not yet appropriate for industrial usage, especially when compared to other strengthening techniques.

Nonetheless there have been recent developments in using ring shapes and thicker, cylindrical samples. The larger volume available from these techniques may enable a more widespread adoption.

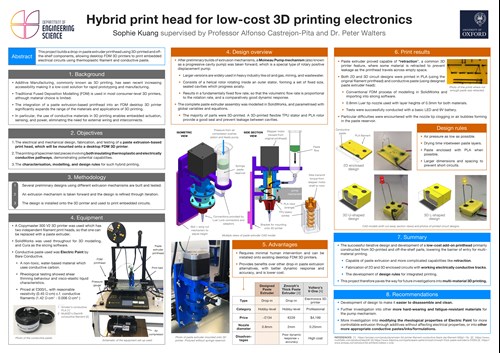

Supporting document for Sophie Kuang

This project centres around the design, development, and testing of a paste extruder printhead which can be mounted onto an existing desktop FDM 3D printer, focusing on its application in printing embedded circuits using conductive paste and thermoplastic filament.

The main objectives of this project were:

1) The electrical and mechanical design, fabrication, and testing of a paste extrusion-based print head, which will be mounted onto a desktop FDM 3D printer.

2) The printing of specimen test pieces involving both insulating thermoplastic and electrically conductive pathways, demonstrating potential capabilities.

3) The characterisation, modelling, and design rules for such hybrid printing. which were achieved through, firstly, the preliminary testing of several extrusion mechanisms; then, the further iterative development of a selected extrusion mechanism; and finally, the installation of this extruder onto a 3D printer and printing of embedded circuits.

The final paste extruder design uses a Moineau pump, otherwise known as a progressive cavity pump. It consists of a helical rotor rotating inside an outer stator, the space between which form a set of fixed size, sealed cavities which progress axially. This provides a volume flow rate proportional to the rate of rotation and a comparatively good dynamic response compared to other mechanisms. It also later proved capable of retraction, a common feature in 3D printers where some material is retracted to prevent leakage as the printhead travels across empty space.

SolidWorks was used to model and parametrise the assembly using global variables and equations. Most of the parts were 3D-printed or otherwise off-the-shelf components. In particular, the rotor was 3D-printed in PLA; the stator, in flexible TPU, to provide a good seal and prevent leakage between the cavities. The paste extruder was then mounted onto a 3D printer and was used to successfully print both 2D and 3D circuit designs using conductive paste and PLA. Tests were conducted with a basic LED and 9V battery, and a set of design rules created for integrated printing. This paste extruder thus provides benefits over other drop-in alternatives, with better dynamic response and accuracy, as well as being capable of more complicated capabilities like retraction.

Minimal human intervention is required, and it can be installed onto existing desktop FDM 3D printers easily as its stepper motor is sourced from the original print head. It is also lower cost, with a total costing of just over £130.

This project therefore paves the way for future investigations into multi-material 3D printing. It proves that it is possible to use 3D-printed parts and off-the-shelf components in the build of a lower cost and more capable paste extruder. This lowers the barrier of entry for the use of conductive materials in 3D printing, enabling embedded actuation, sensing, and power, without external wiring or interconnects, which has potential applications in wearable technology, sensors, and robotics.

Further investigation into modifying the rheological properties of the conductive paste used without affecting its electrical properties, or other more appropriate formulations, is recommended.

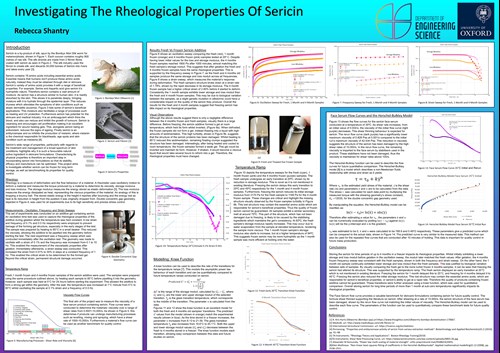

Investigating the Rheological Properties of Sericin Rebecca Shantry Sericin is a by-product of silk, spun by the Bombyx Mori Silkworm for metamorphosis. The silk strands are made from 2 fibroin fibres coated with sericin. The silk industry uses the fibroin to create silk, and discards 50,000 tonnes of Sericin into rivers and lakes every year.

Sericin’s wide range of properties, particularly with regards to the treatment and management of a broad spectrum of skin conditions, highlights why it is such a favourable natural active ingredient in skincare formulations. Characterising its physical properties is therefore an important step in incorporating sericin into formulations so that its stability, efficacy and manufacture can be optimised.

This project aims to investigate whether sericin can be frozen for long term storage, as well as benchmarking its properties for quality control. This will be achieved by using fresh sericin additive samples to create benchmarks which the frozen samples can then be compared to. Oscillation, frequency and strain sweeps were conducted to determine the properties during gelation, after gelation and during deformation respectively.

The results showed freezing had little impact on the sericin’s rheological properties. However, visually there was a large difference, the fresh sample formed a gel, whereas the frozen sample thawed into a liquid with high amounts of sedimentation. Therefore, a temperature was performed, comparing the fresh to the frozen samples. This highlighted the missing structure seen visually, this structure could contain the amino acids that provides sericin its incredible properties, thus the quality could not be ensured after freezing.

The second part of the project was to determine the flow curves for a sericin face serum. This is necessary to see if the solution can be mixed, levelled or will flow in a pipe for future mass production. It is also crucial for quality control. The data collected will be used for the company Nativis which is planning on selling to consumers in a year’s time.

In the future, the companies will expand into the medical industry due to sericin’s potential as an antimicrobial, antitumour, antioxidant as well as its ability to promote healing and rapidly form a wound healing gel. Thank you for taking the time to read my poster.

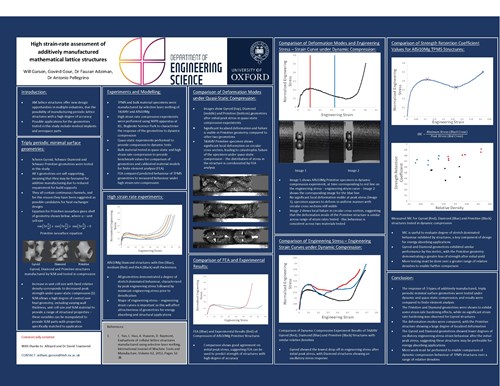

Additive manufacturing (AM) is a powerful tool in designing novel parts in various industries, enabling new designs to be produced that cannot be manufactured using traditional manufacturing techniques.

The potential uses of AM parts are wide-ranging, and various research efforts have been undertaken to ascertain the suitability of the new designs for industrial use, particularly in the medical industry. Several studies have been untertaken to show the effectiveness of porous implants in reducing the stress shielding effect, which occurs due to a difference in stiffness between an implant and the surrounding bone.

Porous implants have also been shown to improve bone ingrowth and binding forces between implant and bone. Additionally, reduction of system weight is critical for aerospace and automotive industries, and AM aerospace parts have been designed to simultaneously reduce system weight and improve functionality. Triply periodic minimal surface (TPMS) geometries represent an opportunity to exploit the increasingly wide use of AM in industry and demand for increased efficiency through the manufacture of lightweight load-bearing components with customisable properties.

The periodic lattice structures may enable designers to manipulate geometrical parameters to create parts with improved functionality and lower weight, presenting a range of opportunities for reducing system weight and improving space efficiency. However, understanding of the characteristics of these geometries must include the dynamic compression response to deploy the lattice structures as effectively as possible. Ti6Al4V is a titanium alloy that has been regularly used in additive manufacturing experiments due to its manufacturability.

The alloy has been commonly used in the aerospace, automotive and medical industries, due to its favourable properties including high strength-to-weight ratio and fracture toughness. AlSi10Mg is an aluminium alloy used in the aerospace and automotive industries, due to its high strength-to-weight ratio and low density. AlSi10Mg has been identified as an important material in the research of TPMS structural performance due to high industrial demand for lightweight components with high strength.

The aim of this project was to characterise the response of 3 triply periodic minimal surface (TPMS) geometries to high strain rate and quasi-static compressive loading. The geometries were produced by additive manufacturing, using selective laser melting (SLM) of the Ti6Al4V and AlSi10Mg alloys. The manufactured specimens were tested on the Split Hopkinson Pressure Bar (SHPB) testing apparatus and screw-driven quasi-static testing machines at Begbroke Science Park. Finite element analysis (FEA) of dynamic compression of the geometries was also performed.

The dynamic compression performance of Gyroid, Diamond and Primitive TPMS geometries with a range of wall thicknesses were compared for both Ti6Al4V and AlSi10Mg structures. Each testing condition was then compared to quasi-static experiments and FEA results. Strength Retention Coefficient values were calculated to quantify the degree of oscillatory engineering stress-strain behaviour exhibited by the structures.

The deformation modes of the geometries were compared for the quasi-static testing condition. Finally, the suitability of each TPMS structure for dynamic load bearing structures was discussed and recommendations for future work were made.

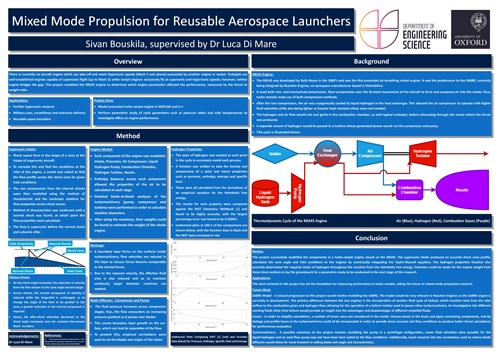

Mixed-Mode Propulsion for Reusable Aerospace Launchers, Sivan Bouskila, St John’s College

Turbojets are well-established engines capable of supersonic flight (up to Mach 4). The scramjet engine, of which a handful have been successfully developed and tested, is a power-plant that flies exclusively at supersonic and hypersonic speeds (defined as a velocity greater than Mach 5). However, there is no commercial air-breathing engine that can perform a horizontal take-off at sea level and then bring an aircraft to a hypersonic cruise speed. An engine capable of taking off and exceeding Mach 5 would have many uses in both research and defence applications, namely furthering hypersonic research, allowing high speed flight data to be collected, and military surveillance. There are also uses in the aerospace industry for space travel with a cycle where the air-breathing mode could be disabled and an on-board oxidiser used instead.

The process of precooling air in hypersonic air-breathing engines with cryogenic hydrogen was modelled for this project. In particular the optimisation of parameters such as pressure ratios and mass flow rates and their impact on the weight and performance of the engine cycle were studied. This was attempted through MATLAB and C++ models of an engine similar to the RB545 engine developed in the 1980's.

In order to investigate the engine cycle and its parameters, research on past hypersonic engines was conducted to identify common successful traits. A working model of the engine and its components was also made. The complete model was composed of a supersonic intake, an engine, and a hydrogen properties function to model the hydrogen fuel. Once accomplished, it was concluded that the model could be used to measure performance, given some optimising of the engine model. The supersonic intake model successfully solved the flow profile at the inlet to the engine and the hydrogen properties function was shown to accurately return hydrogen properties with errors of less than 0.0286 %.

The results of this project, namely the weight estimating of the engine, have set the groundwork for future research into turbo-ramjet performance. It is particularly relevant to Reaction Engines who are developing SABRE, an air-breathing rocket engine, as the RB545 was the predecessor to their design. With some adjustments, this project model can be redesigned for the SABRE to allow a parametric study of its own to be conducted to evaluate the performance of the engine.